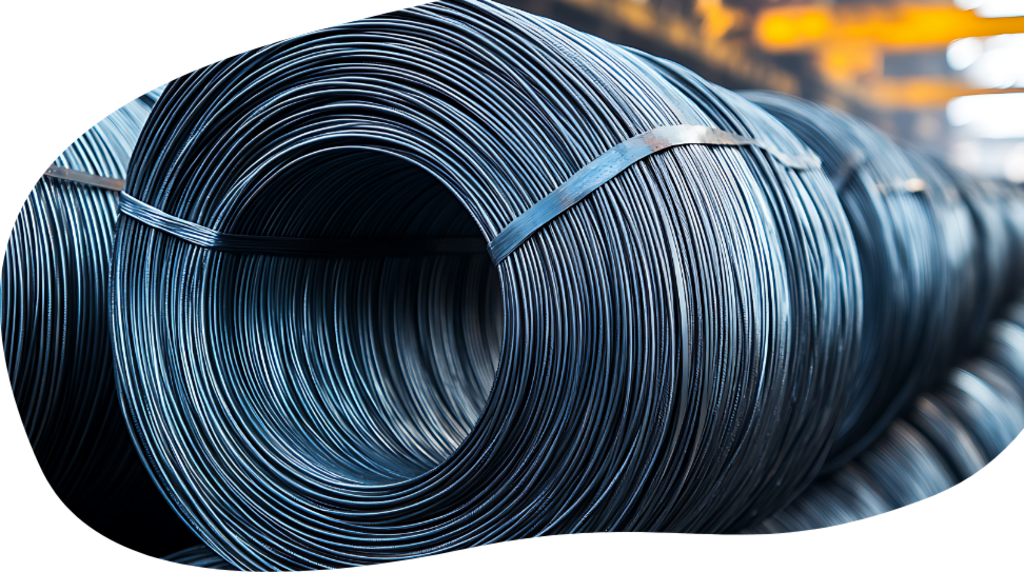

WIRE

See the difference.

WEDOLiT SOLUTIONS FOR WIRE DRAWING

Wire drawing demands exceptional lubrication and surface control to achieve tight tolerances and high productivity. WEDOLiT wire drawing lubricants and corrosion protection agents provide reliable film strength, thermal stability, and easy removability. Whether in dry or wet drawing processes, our solutions ensure consistent wire quality, smooth surfaces, and corrosion-free storage and transport.

KEY TECHINCAL CHALLENGES

- High friction and thermal stress:

Fast wire movement and die contact generate significant heat, risking lubricant breakdown and thermal damage to wires and dies. - Die and tool wear:

Continuous use causes die wear, increasing the risk of wire breakage and dimensional issues. Effective lubrication and regular maintenance are essential.

- Lubrication under extreme conditions:

At high drawing speeds, standard lubricants may lose viscosity and film strength, leading to higher friction, greater wear, and surface defects. Selecting the right lubricant is critical. - Post-drawing cleaning: Lubricants must be easy to remove. Residual oil can hinder downstream processes such as coating, welding, or plating and raise production costs.

SEE THE DIFFERENCE

With more than 80 years of experience, WEDOLiT is a trusted partner in metal forming and corrosion protection. From our Technology Center in Düsseldorf, our dedicated R&D team develops advanced, high-performance solutions tailored to your needs.

Connect with our experts and SEE THE DIFFERENCE that innovation and expertise can make.