CORROSION PROTECTION

See the difference.

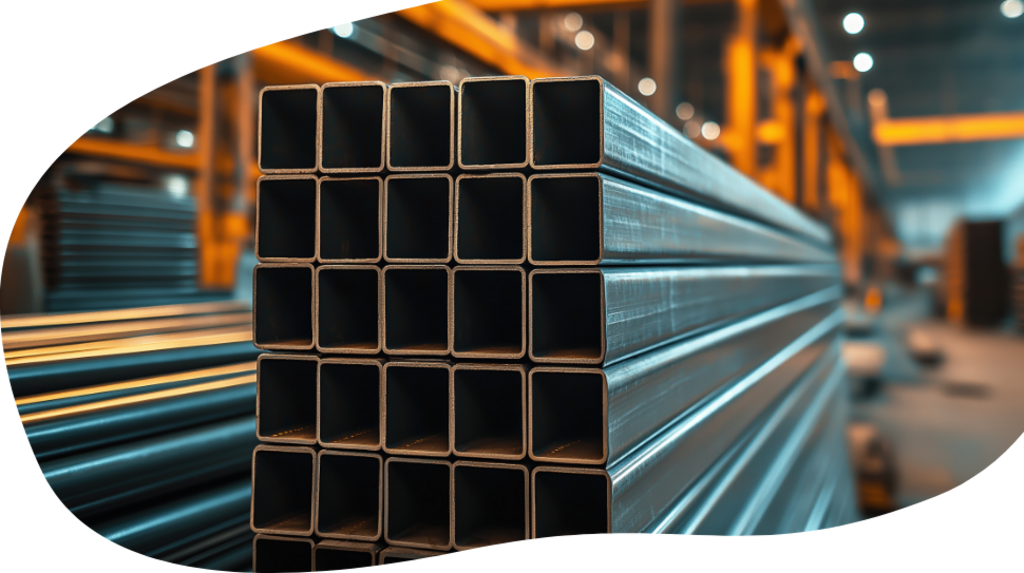

WEDOLiT SOLUTIONS FOR TEMPORARY CORROSION PROTECTION

Temporary corrosion protection is an essential part of every metalworking process. From production and interim storage to global shipment, metals are exposed to humidity, temperature fluctuations, and corrosive gases that can quickly cause surface degradation. WEDOLiT corrosion protection products ensure that components remain clean, dry, and free from rust throughout the entire logistics chain.

UNTERSTANDING THE TECHNICAL CHALLENGES

Even minimal traces of moisture or contamination can initiate corrosion. Conventional lubricants such as greases or hydraulic oils provide lubrication but not reliable long-term protection. Effective corrosion protection requires barrier-forming films that resist oxidation, displace water, and can be easily removed before further processing.

According to DIN 50902, temporary corrosion protection refers to protection during periods of storage, transport, or standstill using easily removable media such as oils, waxes, or aqueous inhibitors.

THE COMPLETE WEDOLiT PORTFOLIO

CORROSION PROTECTION OILS

Form thin, efficient films that shield metal surfaces from air and moisture.

DEWATERING FLUIDS

Displace residual water and create a uniform, protective layer on moist parts.

AQUEOUS INHIBITORS

Clean and protect simultaneously, ideal for in-process or short-term storage.

WAXES

Provide durable protection for extended storage or overseas shipment.

COMPATIBILITY WITH VCI PACKAGING

Fully compatible with vapor-phase corrosion protection systems.

SEE THE DIFFERENCE

With more than 80 years of experience, WEDOLiT is a trusted partner in metal forming and corrosion protection. From our Technology Center in Düsseldorf, our dedicated R&D team develops advanced, high-performance solutions tailored to your needs.

Connect with our experts and SEE THE DIFFERENCE that innovation and expertise can make.